The team of Prof. Dr. Andreas Schütze at the Lab for Measurement Technology targets focuses on measurements of and with microstructures.

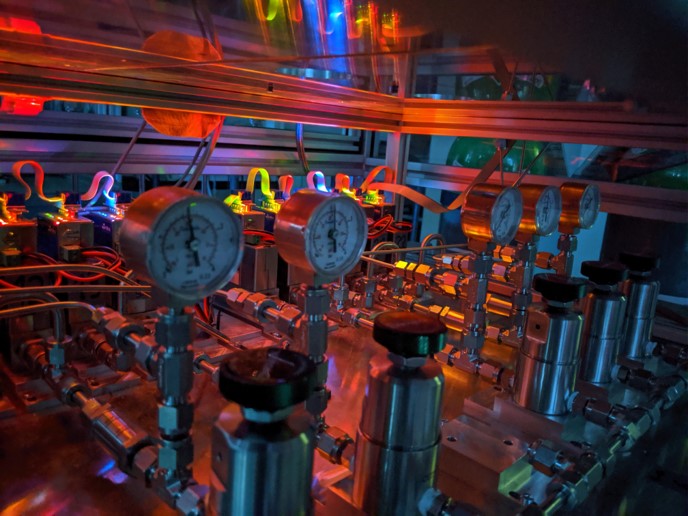

One focus is gas measurement systems, in particular the intelligent evaluation of multi-dimensional data structures of sensor arrays and virtual multi-sensors, i.e. dynamically operated, individual sensors, as well as the complex calibration of the sensor systems that is absolutely necessary for achieving high performance. The methodological solutions are tested, e.g. in the field of Green Buildings, e.g. for optimized ventilation to balance air quality and energy consumption, but also in safety applications and odor evaluation.

Our second focus, located in the research group Data Engineering and Smart Sensors at ZeMA, is targeting AI for industrial process control and condition monitoring. Here, methods of machine learning, in particular pattern recognition, are applied, often directly using process sensors, to determine the system status as a basis for service on demand, but also for process integrated quality control. In our projects, we primarily deal with the question of how to get the intelligence into the sensor, i.e. with distributed AI or edge computing, in which the first stage of signal evaluation and evaluation takes place directly within the smart sensor.

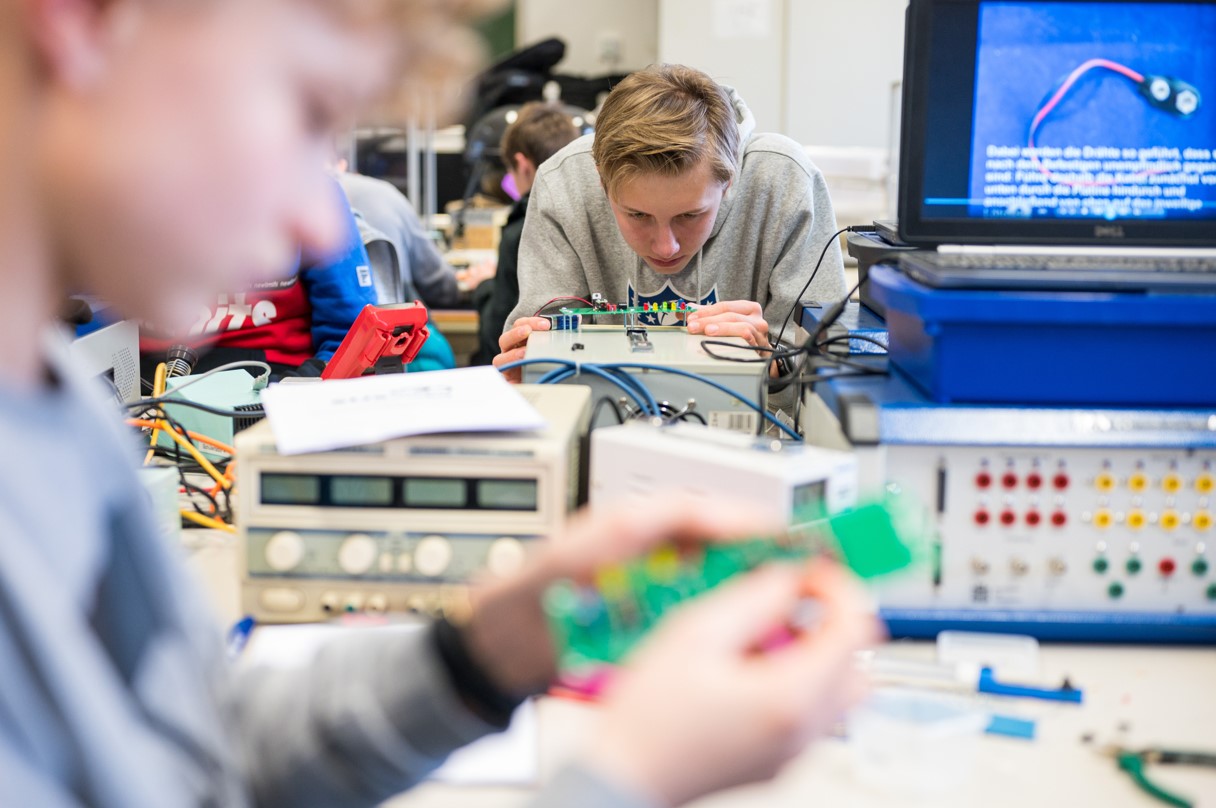

A third focus is addressing outreach activities and Public Understanding of Science and Humanities (PUSH). We want to support young talents especially demonstrating the fascination of hightech solutions. We use the "technical senses", the sensors, to bring schoolchildren closer to the latest technology, primarily through the school laboratory SinnTec and the high school student internship IngFo.

Our R&D focus areas:

Gas measurement systems |

Data Engineering & Smart Sensors |

Hightech outreach |

intro video (German only) |

intro video (German only) |

intro video (German only) |

Application fields

- Green buildings/ energy efficiency: optimized ventilation for Indoor Air Quality (VOC, CO2)

- Industrie 4.0: Condition Monitoring based on Machine Learning (statistical pattern recognition)

- Renewable energies, e.g. Condition Monitoring in wind turbines, sensors for DMFC

- Food quality and waste prevention

- Safety: Leak detection, explosion warning, fire detection

- Niche applications: e.g. odor monitoring for industrial installations, clothes etc.

- further possible fields of application are medical, environmental monitoring and recycling

R&D focus areas

- Air quality, especially selective detection and quantification of hazardous VOCs for indoor air quality; projects:

- VOC4IAQ

- EuNetAir

- SENSIndoor

- VOC-IDS

- Micro gas sensor systems and sensor arrays/virtual multisensors

- Measurement systems for sensor characterization and calibration of sensor elements and sensor systems

- Sensor self-monitoring based on dynamically operated sensors, e.g., für metal oxide semiconductor (MOS) gas sensors or amperometric oxygen sensors

- Condition Monitoring of industrial systems (e.g. mechatronic, hydraulic or pneumatic components or systems) based on statistical data analysis, also able to recognise sensor faults; projects:

- MoSeS-Pro

- KI-Predict

- KI-MUSIK4.0

- BetoNPP

- IR sensor systems for online oil quality monitoring and characterisation of fluid mixtures

- Characterization and selection of commercial microsensors for specific applications

- Development of adapted operating modes (dynamic measurements, temperature cycles, etc.) for specific applications

- Multivariate data analysis and multisensor signal processing, up to deep learning

- Development of a hardware and software platform for the universal control of digital and analog semiconductor gas sensors